Not too long ago, Supply Chain consisted mainly of a set of formulaic methods and processes. Back in those simpler days, labels were transparent: manufacturer, distributor, wholesaler, and retailer. Not anymore. Today, if an organization has to succeed amidst intense competition, they have to quickly respond to dynamic customer requirements. The only way to achieve that is to leverage technology. Little wonder why, across industries, manufacturers are increasingly using digital enablement to reach customers directly, while at the same time, the likes of Amazon continue to disrupt the way customers acquire products and services, leading to a market where companies partner and compete with one another simultaneously. Multi-brand omni-channel has helped companies cater to customer requirements and help boost their business. That being said, I strongly believe that the key to survive in a dynamic market lies in enhanced planning and it is remarkably different from what it was a few years ago.

Advances in technology has resulted in automation and streamlining of a large chunk of complex Supply Chain processes. Businesses are focusing more on proactive supply chain analytics solutions to help them make better decisions. According to IDC, by 2021, 60% of manufacturers will be leveraging an advanced analytics-driven data aggregation platform for supply chain operational data to augment the speed and accuracy of the fulfillment process.

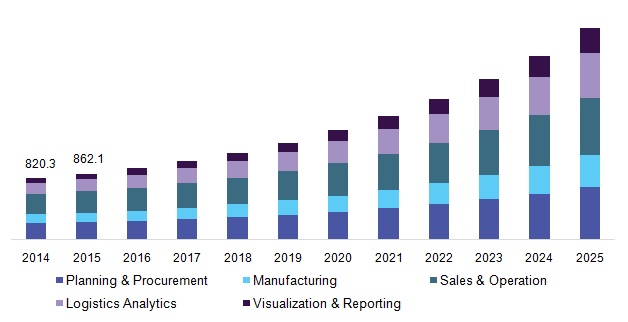

U.S. supply chain market, by solution, 2014 – 2025 (USD Million)

Image source: https://www.grandviewresearch.com/industry-analysis/the-global-supply-chain-analytics-market

In the world of Supply Chain, some of the biggest areas of opportunity for an organization lie in its ability to promptly and accurately identify market movements and trends, while achieving optimal inventory. Demand forecasting using data and supply chain analytics should be the foundation of the process. This is crucial for future leaders to precisely identify market trends and inventory optimization. In addition, making demand forecasting enables an organization to optimally use their resources for enhanced revenues. For instance, one of our clients – a large and prominent snack company was experiencing low capacity utilization in few of their expensive production equipment. LatentView Analytics used ad-hoc supply chain analytics on the data generated by machine sensors to develop an early warning system that prevented breaks in the line. This increased the production output by 6%, thereby saving millions of dollars in operational costs.

Supply Chain forecasting uses machine learning on unstructured data to derive actionable insights that benefit inventory planning and restocking. While a few organizations are looking at speed to understand markets as a value creating differentiator, advanced tools and techniques do provide incremental improvements on forecasting capabilities. LatentView Analytics has drawn from this understanding to develop an innovative approach to creatively look at unstructured data and dramatically increase the accuracy and speed of demand forecasting.

Let me share another example here. We got in touch with a major home appliances and repair services provider who had a rudimentary forecasting process with functional areas, each having their own requirements. In addition to forecasting accuracy and additional algorithms and techniques, we looked at data such as weather that helped improve demand forecasting from 65% to 92%. A properly balanced inventory enabled them to effectively respond to business calls resulting in millions of dollars of additional revenue.

In conclusion, I strongly believe that supply chain executives are now presented with an opportunity to leapfrog competition that continues to use an incremental approach, using on expensive internal platforms. To be successful, it’s time for companies to do things differently by leveraging solutions that are uniquely designed for their needs, vision and goals. Agile, proof of concept pilots are sensible and smart investments that can lead to business transforming breakthroughs. In a business environment that continues to transform at such a fast pace, having the right partner to match this speed and accuracy will be of the essence.