The ever-increasing demand clusters for a given geography and supplying them with the optimal resources in the current fast-paced retail and service industry leads these industries to rework their supply chain channels with the application of advanced Machine Learning and Neural Network algorithms. Using supply chain analytics, a business can make accurate forecasts of what the overall demand will be. Apart from this,it is also important for them to successfully fulfill the demand across different segments and timely supply those desired signals. Demand fulfilment from limited number of Big Demand Centers is not enough; the business needs to improve their localized fulfillment centers or warehouses across geography to improve their overall fulfillment rate and customer satisfaction.

Due to increase in the market challenges and competition, the traditional business models can no longer keep up with supply interruptions. There needs to be a strategic roadmap for demand prediction and management and sustainable supply chain optimization framework across the varied demand centers to build an efficient supply chain system.

While demandfulfillment can be improved by a brute force method of inflating the inventory space in the warehouse, it would come with huge holding costs across all market segments. This will incur the business a cost of carrying the inventory – Holding cost, which will affect the profit margins inversely. This is a risk that businesses cannot afford. This is where optimization comes into play by ensuring that demand meets supply while simultaneously reducing inventory costs.

Key challenges to improve demand fulfillment rate

Some key challenges for improving the fulfillment rate for the demand centers involve the following:

- Complex sale compositions – In today’s large space of the retail and services industry, which caters to the consumers via multiple channels, the complexity of the supply chain increases with the increase in the variety of products and services offered. This can lead to excess stocking of SKU’s which entangles working capital and margins.

- Volatile customer demand – The demand patterns from the customers are prone to varied seasonal patterns and promotional activities, this can lead to interruptions in the supply chain if not gauged properly.

- Scalability of the demand centers – Without proper planning to ensure scalability of demand center, fulfillment issues are unavoidable. It leads to logistical and capacity struggles regardless of financial support.

- Optimal movement of resources across demand centers – The unavailability of resources at the demand centers when the requirement arrives can cause the business additional logistics costs from transportation and shipment to achieve the fulfillment goals or lose out on the customer loyalty and satisfaction if ignored

- Flexibility to account for network changes – The supply chain process should be flexible enough for any dynamic changes, to avoid disruptions. According to Choy et al. (2008) increasing flexibility in the supply chain can be regarded as a strategy for improving system’s responsiveness to change. A famous example in this case – a decrease in quarterly earnings in 1996 of $900 million for General Motors was due to an 18-day labor strike at a brake supplier factory that idled workers at 26 assembly plants.

- Inventory depth and availability – For high selling volume of inventory or resources, it is comparatively uncomplicated for the stakeholders to achieve high fulfillments, but for the low selling ones, the business needs to have an exceptional understanding of the accurate inventory depth across the demand centers while maintaining high fulfillment rates.

- Accurate depiction of the supply chain – Any industry dealing with the supply chain fails to achieve targets if there are no business judgements involved. Lack of a holistic view of the entire cycle will lead to gaps not being fulfilled across multiple market segments and channels.

Process map to achieve high demand fulfillment rates

Fulfillment rate can be a key metric that can impact the business outcome and the perception among the consumers which can set the brand ahead of its competition by a huge margin. This makes sense in the long run where the business can incept themselves in the minds of consumer and the popularity can promote the brand to achieve higher profits.

At the core of supply chain, we have two major nodes in the pipeline – Demand and Supply. The Fulfillment Rate KPI which we are trying to achieve will depend majorly on these two parameters:

- Demand prediction from the consumers

- Movement of the resources and inventory across demand centers optimally.

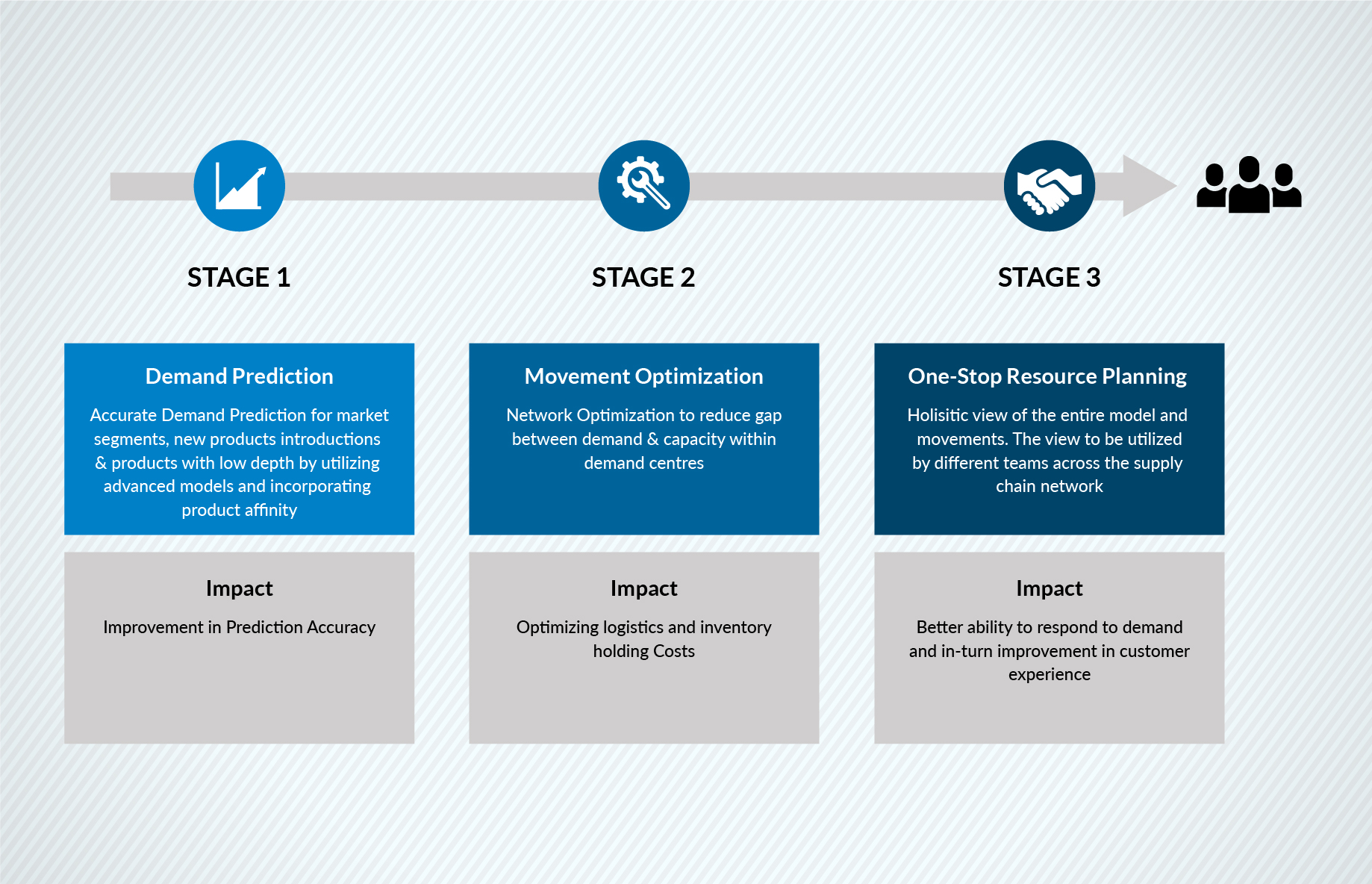

The process map here includes these stages as well as a final component to address the challenge of accurately depicting the Supply Chain KPIs for the actions to be taken from the insights.

Demand prediction:

- Build demand prediction models leveraging the Machine Learning and Neural Network Algorithms with the following:

- Feature engineering to incorporate better indicators of seasonality, trend, & other low depth SKUs.

- Extraction of features from product images for improved prediction for NPIs.

- To improve fulfillment for bundle/basket orders using Product Affinity analysis. This helps in addressing the challenge to achieve higher fulfillment rates for low depth inventory items.

- Using clustering algorithms to gauge the upcoming trends and sales pattern for new products.

- Analyzing segments and design clusters with higher error for demand prediction.

- Iterating through different Machine Learning and Neural Network ensemble models to obtain more stable and accurate predictions.

Movement optimization:

- Identify demand clusters & products with low fulfillment rates.

- Non-linear and Convex algorithms to move the inventory and resources optimally for the demand centers.

- Merge the allocation outputs for the movements with the business rules and judgements.

- Enhance the logic by accounting for product affinity while moving inventory and resources.

- Optimizing shipment priority (Standard vs Express).

- Network optimization of SKU and Resource movements to reduce gap between Demand & Capacity, consequently reducing shipment & holding cost.

One-stop resource planning:

- Output of Demand Prediction & Inventory Movement to be utilized by:

- Merchandising

- Demand Planning

- Inventory Analysis

- The consolidated view merges the Machine Learning and Neural network prediction outputs along with the Optimized movements and allocations in a single frame.

- Leverage the methodologies to monitor the supply chain accurately for the stakeholders to take actions and induce business signals.

- The entire engine and planning work concurrently to achieve high order of fulfillment rates and consequently improve customer satisfaction

Conclusion

Success in the fulfilment rate relies on accurate results, key-quick decisioning from the business and dynamically gauging the impact from those decisions. This can be achieved with the process map as outlined above, which enables the organization to have an edge in this competitive era of ‘Customer-centric’ culture in the retails and services industry

With an effective and optimal allocation of resources to match the demand, not only will the business ensure higher fulfillment rates, but they also succeed in higher profit margins and brand satisfaction which changes the way the brand is perceived by the consumer.

Advanced analytics in supply chain to drive customer-centricity

The advent of supply chain analytics has changed the way supply chains are positioned. Modern supply chains are more connected, agile, efficient, and customer-focused. An omni-channel strategy has been one of the biggest disruptions in the retail industry, and organizations are looking at is as a money-spinning opportunity, by leveraging digital supply chain analytics. To learn more about how to use the supply chain analytics for driver higher fulfillment rate, please write into: sales@latentview.com