Manufacturing is one of the most important industries in the world’s economy. It accounts for ~16% of global GDP in 2019 and has generated an output of 13.9 trillion globally. US and China are the leading manufacturers globally, accounting for 4 trillion and 2.5 trillion manufacturing output respectively in 2019. India stands at 5th position with 0.42 trillion output, approximately 3% of the global output value.

This blog throws light on the impact of COVID-19 on the Manufacturing Industry, the analytics opportunities, and how analytics and automation can assist businesses during unforeseen situations.

The Effect of the Pandemic on the Manufacturing Industry

COVID-19 has impacted the manufacturing industry severely, and in the second and third quarter of 2020, global manufacturing output has declined by 11.1% and 1.1% in a year-on-year comparison. Industries worldwide have been affected by COVID-19, but the Aviation and Automobile industries were affected the most.

One of the most important metrics used to measure growth in the manufacturing industry is Purchasing Managers Index (PMI). It is a survey-based measure derived from private sector companies. If PMI is below 50, it means there’s a contraction, and anything above 50 shows an expansion. Due to the US-China trade war, the global PMI decreased to 49.8 in May 2019. Hence, the trade war caused a recession in the industry much before the pandemic. In March 2020, the PMI further contracted to 43.6. The lowest PMI was recorded in April 2020 when it dipped to 32.5, but it rebounded to ~47 in June 2020.

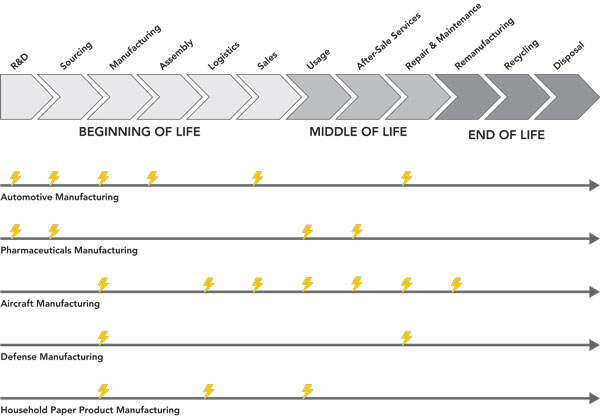

The COVID-19 impact varies across industries. The visual below illustrates the effect of COVID-19 on different manufacturing stages across different types of manufacturing industries.

The Automotive manufacturing industry is mostly impacted at the beginning of the manufacturing cycle, whereas the Aircraft manufacturing industry is heavily affected in the middle of the process. All the industries are affected at the manufacturing stage except for the Pharmaceutical manufacturing industry.

The challenges faced by industries also vary. For, e.g., Pharmaceutical is experiencing unforeseen demand for medical supplies and is struggling to ramp up production. In contrast, there is a steep fall in demand in the Aviation and Automobile industries. Rapidly changing regulations, such as trade restrictions and demand shocks, have severely impacted Logistics providers.

Among the top 10 countries, China is expected to make the quickest recovery. Germany, the key player in the Automotive Manufacturing industry, is expected to make the slowest recovery since it relies heavily on exports.

Will Smart Manufacturing be a Game-Changer?

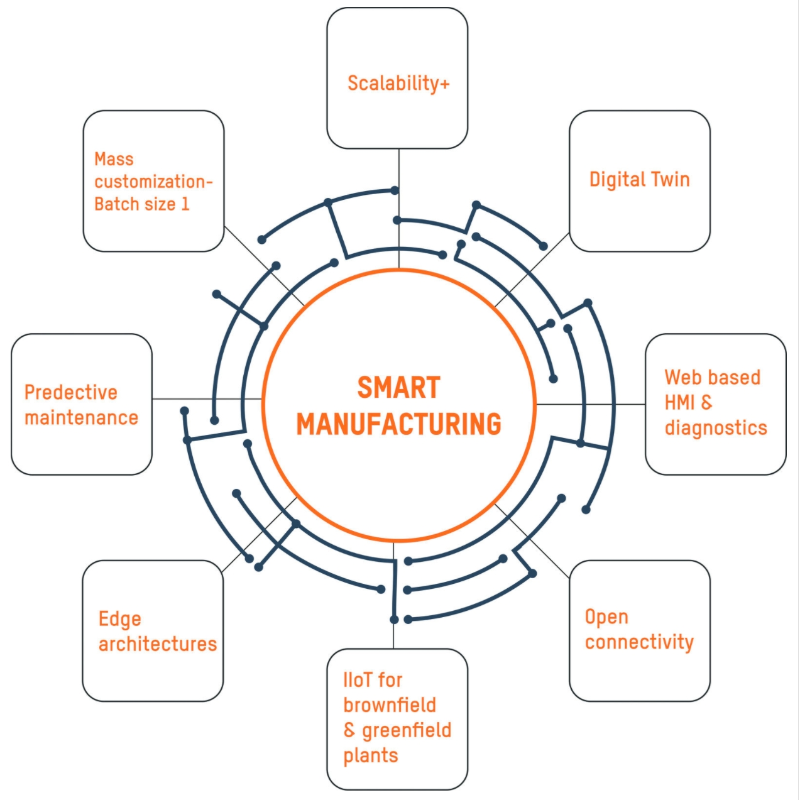

Smart Manufacturing is an emerging sector in Manufacturing that opens doors for analytics in the industry. It is a technology-driven approach that utilizes the Internet of Things (IoT) and Internet-connected devices to produce goods and monitor services. It aims to automate the processes involved in Manufacturing for better efficiency, sustainability, supply chain management and identify the system’s bottlenecks even before they occur.

Global Smart Manufacturing revenue before COVID-19 was around $171.5 billion and is expected to reach $303 billion by 2026 at a CAGR of 6.4 %.

Global Smart Manufacturing is segmented by Component, Application, End-use, and Region.

Aerospace, Defence, and Pharmaceuticals manufacturing sectorsare expected to exhibit high growth, and region-wise, APAC is expected to hold the largest market share. Component-wise, the software segment is likely to emerge as the fastest-growing segment due to increasing factory automation software demand.

Drivers of Smart Manufacturing growth :

- The rise in the use of industrial automation in manufacturing and government investments supporting the same

- Increasing emphasis on regulatory compliances

- Increased complexities in the supply chain

- Growing demand for software systems that reduce time and cost

The Need of the Hour: Manufacturing Analytics

Today, Industrial Internet of Things (IIoT) and Digitalization are no longer a choice. It has become imperative to drive things by leveraging analytics and automation in all sectors, including Manufacturing, to generate impactful results and insights for greater efficiency and accurate results. The Manufacturing Analytics market is projected to grow at 16.5% CAGR by 2026 and the fastest in North America. The current global manufacturing analytics market size is about $5.9 billion, which is predicted to reach $28.5 billion by 2026.

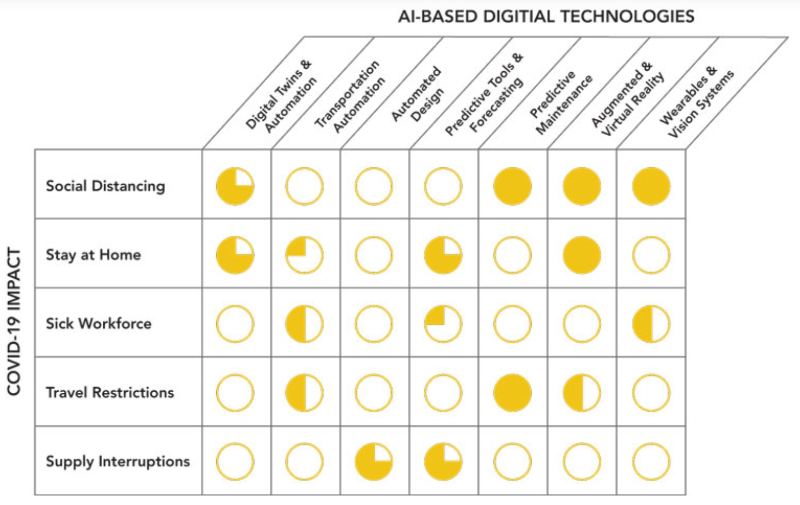

Smart use of technology and AI can help grow and drive the business by overcoming the limitations imposed due to the pandemic. The visual below illustrates how AI can leverage the impact of COVID-19 in the Manufacturing industry.

Here are some areas where we can use analytics in the manufacturing industry to amplify the growth:

- Inventory Management: Real-time insights and visibility into inventory even along the supply lines, along with delivery route optimizations, helps in bringing down warehousing cost.

- Predictive Maintenance & Asset Management helps increase assets’ lifetime, improve asset availability, and prevent unplanned downtimes.

- Achieve target sales using advanced reporting tools for forecasting demand.

- The newest IoT solutions for asset management include real-time alerts, allowing manufacturers to take action to minimize loss associated with delayed, damaged, or lost goods in transport.

- Data analytics can significantly improve assembly-line efficiency. For example, a pin-point defect scan can help in defect elimination leading to vastly improved quality and increased productivity.

- Through analytics-backed simulations, product modeling helps reduce errors and corrections during product development, improving the product’s quality and packaging.

- Networked Manufacturing: Costs and logistics optimization.

- Improved Customer Experience, including personalization and finding individualized value propositions.

- IoT tech such as location-based services provides increased visibility into the supply chain with actionable data for preventive maintenance and proactive risk mitigation.

There is no doubt that AI is the manufacturing industry’s future, and the market is already growing for digital technologies. AI-enabled digital technologies not only addresses product lifecycle issues but also increases visibility and transparency across supply networks. AI is no longer going to be a choice. It will become a necessity in the coming years for businesses to sustain in the manufacturing market.

Visit our Business Analytics page to know more about what we do.